The use of pelletizing systems

Pelletizing systems play a crucial role in polymer production by ensuring the safe, efficient, and profitable processing of various materials, including standard plastics, biopolymers, hot-melt adhesives, and engineered plastics.

In the pelletizing process, molten polymer is cut into uniform pellets. These pellets serve as the raw material for various industries, including packaging, automotive, electronics, and textiles, where they are melted and molded into final products.

MAAG’s advanced pelletizing solutions include:

- Strand pelletizing

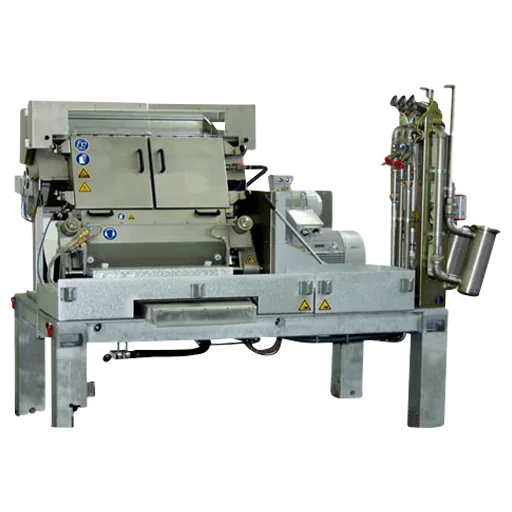

Advanced wet cut, dry cut, and pultrusion systems tailored to the polymer industry. From lab-scale strand cutters to high-performance production solutions, MAAG delivers innovative designs to meet evolving market needs. - Underwater pelletizing

MAAG’s underwater pelletizing systems, blending Gala and Automatik expertise, deliver superior quality and performance, even for toughest challenges. Custom tools and advanced designs ensure unmatched results for polymer pelletizing. - Drop pelletizing

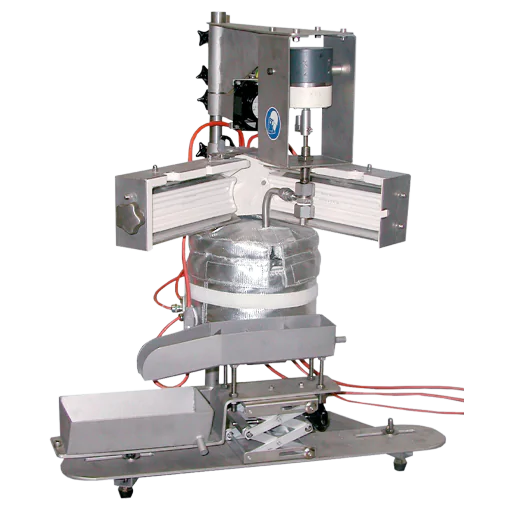

Dedicated systems for perfectly uniform, dust-free spherical pellets from low viscosity melts and liquids. Highly efficient and minimal energy use. Perfect for plastics, food, and pharmaceuticals, it ensures durability and precise processing. - Dryers

Advanced centrifugal and belt dryers, tailored for efficient drying of various pellet types, including spherical, abrasive and brittle pellets such as glass fiber or mineral-filled compounds.

Additionally, MAAG provides solutions for recycling plastics, contributing to sustainability efforts. Key advantages of these systems include high efficiency, dust-free pellet production, and adaptability to various polymer types, making them essential for modern polymer manufacturing.